We build software to automate warehouse operations

Reliable solutions from experienced developers who know logistics from inside

Want to see if automation makes sense for your warehouse?

We can review your current process and suggest practical improvements

Typical warehouse problems we help to solve

Based on real systems we’ve built and supported ourselves

Shipping label automation

The Problem

Creating shipping labels manually through carrier websites wastes time and causes mistakes.

What we built

We connected carriers directly via API and automated label creation, tracking updates, and shipment data flow.

Custom warehouse management system

The Problem

Inventory tracked in spreadsheets leads to lost parcels, confusion, and no real-time visibility.

What we built

A simple, custom WMS tailored to real warehouse workflows: receiving, storage, picking, and client access via API.

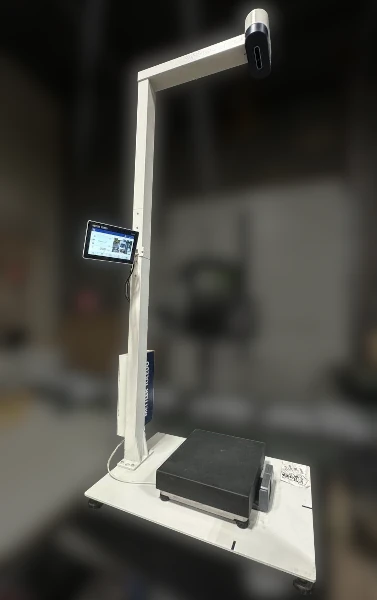

Automated receiving and measurements

The Problem

Manual weighing and measuring slows down receiving and creates queues during peak hours.

What we built

Integrated camera-based dimensioning and industrial scales directly into the receiving process.

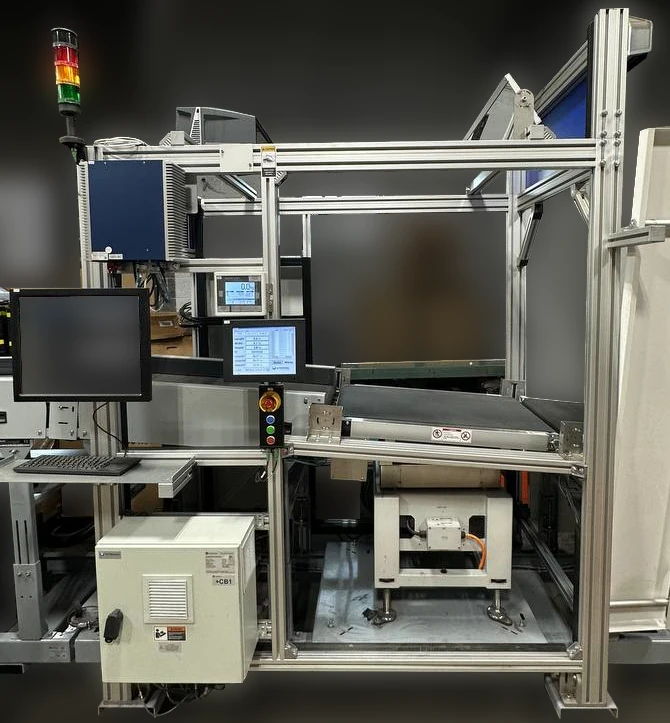

Parcel sorting automation

The Problem

Delayed parcels were sorted manually — slow, error-prone, and physically exhausting for staff.

What we built

Software integration for an automated conveyor with routing logic based on parcel data.

Automatic label printing and verification

The Problem

Manually applied labels lead to unreadable barcodes and carrier rejections.

What we built

Integrated automatic label applicator with print verification and warehouse software.

WhatsApp integration for customer support

The Problem

Staff had to search across systems while answering client questions in WhatsApp.

What we built

Connected WhatsApp Business API with internal systems so operators see order context instantly.

Who we are and how we work

Hands-on logistics experience

We build and support warehouse systems we actually use in daily operations

Small team, direct communication

You talk directly to the developers — no managers, no layers

Fair pricing

We focus on long-term cooperation, not one-off projects

We stay involved after launch

Bug fixes, small improvements, and support when something breaks

Have a problem in your warehouse you want to fix?

Describe it briefly — we’ll tell you honestly if we can help

Typical response time: Within 24 hours